VA-Standard - 500 GPD Membrane - Filmtec Material

€195.16

Content: 1 Stück

Available, delivery time: 3 - 5 Werktage

Product number: 1000185

EAN: 4260645520400

Weight: 0.9 kg

Length: 285 mm

Height: 94 mm

Width: 94 mm

Product information "VA-Standard - 500 GPD Membrane - Filmtec Material"

500 GPD FILMTEC™ Reverse osmosis-Membranes

FILMTEC™ reverse osmosis (RO) and nanofiltration (NF) elements are solutions for industrial, municipal, commercial and consumer water applications. These reverse osmosis membranes provide high retention of dissolved solids and organics and operate very efficiently at lower pressures.

The 500 GPD FILMTEC™ reverse osmosis membranes also feature excellent structural strength and are more productive than other reverse osmosis membranes. These membranes are applied to demineralise brackish water or seawater desalination for various industries and applications, including industrial water treatment, power generation, food & beverage processing, municipal desalination and water reuse, and at-home drinking water devices.

Features and functions:

Typical applications:

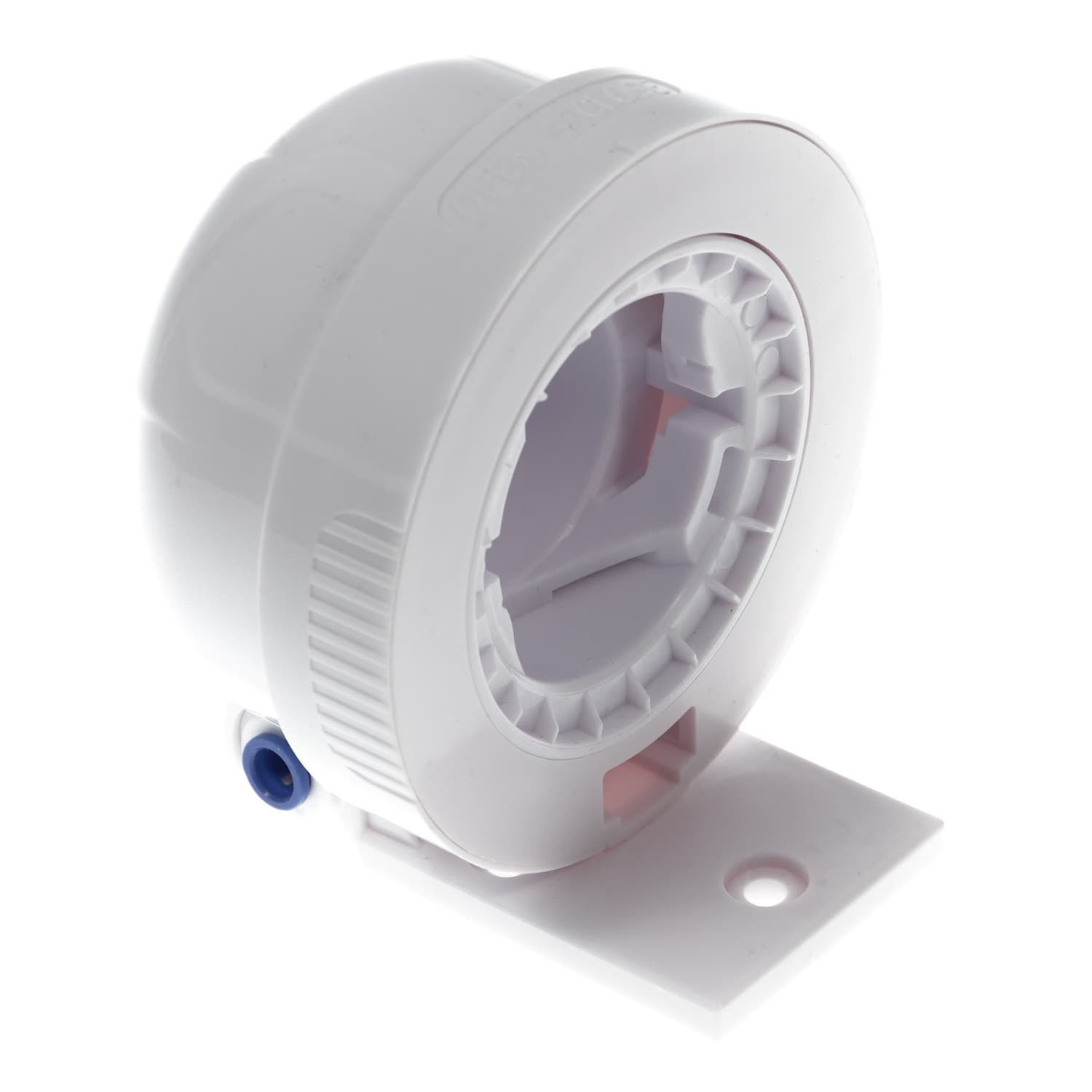

VA-Standard-Cartridge-System

Using a reliable and robust water filter cartridge system in water filters is essential. Often the pre-filters and post-filters in a water treatment system are the Achilles' heel, the so-called weak point, of the water filter. The filter cartridges must withstand pressure peaks of up to 50 bar, which can occur in the water pipes. At the same time, the cartridge must not burst or even pop out of the cartridge head. In addition, the filter cartridge must ensure a high flow rate in connection with the filter medium used.

The VA-Standard-Membrane-Cartridges are sealed using the rotation welding process, which achieves maximum strength.

In addition, the membrane cartridge has seals, which do not need to be cleaned, checked or replaced when changing the filter. With every new membrane cartridge, you also receive new seals.

The connection between the VA-Standard-Membrane-Head and the VA-Standard-Membran-Cartridge is established using a bayonet lock. If the cartridge is under pressure, the connection of the bayonet lock engages more firmly. This makes it almost impossible to loosen or open the connection under pressure. Another feature is the mechanical lock of the water supply in the VA-Standard-Membrane-Head. Two mechanical valves lock the water inlet and outlet in the VA-Standard-Membrane-Head if the VA-Standard-Membrane-Cartridge is removed. This prevents water from running out of the VA-Standard-Membrane-Head in an uncontrolled manner and causing damage to the water treatment system or the environment.

The VA-Standard-Cartridge-System is modern, robust and safe. It is also perfect as an assembly kit to realise your water filter variations.

FILMTEC™ reverse osmosis (RO) and nanofiltration (NF) elements are solutions for industrial, municipal, commercial and consumer water applications. These reverse osmosis membranes provide high retention of dissolved solids and organics and operate very efficiently at lower pressures.

The 500 GPD FILMTEC™ reverse osmosis membranes also feature excellent structural strength and are more productive than other reverse osmosis membranes. These membranes are applied to demineralise brackish water or seawater desalination for various industries and applications, including industrial water treatment, power generation, food & beverage processing, municipal desalination and water reuse, and at-home drinking water devices.

Features and functions:

- Material: TFC (DOW™ FILMTEC™)

- Input water temperature: max. 45 °C

- Operating pressure: 5 - 6 bar

- Permeate production: max. 78 l/h

- pH-range: 2 - 11

- Chlorine tolerance: < 0,1 ppm

- Separation rate: 98%

- Filters up to approx. 1900 liters per day (500 gallons per day)

- Reduction of salinity

- Removal of chemical impurities

- Recovery of ultra-pure water

- Pre-concentration of water streams upstream of evaporators

- Reduction of wastewater volume by increasing water reuse

- Tap water, brackish water

- 2,5", 4", 8" membranes

- Highest retention

- Low energy consumption

- Resistant to impurities

Typical applications:

- Reverse osmosis

- Drinking water

- Ultra-pure water

- Process water

- Food and beverage industry

- Chemical processing

- Metal surface treatment

- Electronics

- Nanofiltration

- Ultrafiltration

VA-Standard-Cartridge-System

Using a reliable and robust water filter cartridge system in water filters is essential. Often the pre-filters and post-filters in a water treatment system are the Achilles' heel, the so-called weak point, of the water filter. The filter cartridges must withstand pressure peaks of up to 50 bar, which can occur in the water pipes. At the same time, the cartridge must not burst or even pop out of the cartridge head. In addition, the filter cartridge must ensure a high flow rate in connection with the filter medium used.

The VA-Standard-Membrane-Cartridges are sealed using the rotation welding process, which achieves maximum strength.

In addition, the membrane cartridge has seals, which do not need to be cleaned, checked or replaced when changing the filter. With every new membrane cartridge, you also receive new seals.

The connection between the VA-Standard-Membrane-Head and the VA-Standard-Membran-Cartridge is established using a bayonet lock. If the cartridge is under pressure, the connection of the bayonet lock engages more firmly. This makes it almost impossible to loosen or open the connection under pressure. Another feature is the mechanical lock of the water supply in the VA-Standard-Membrane-Head. Two mechanical valves lock the water inlet and outlet in the VA-Standard-Membrane-Head if the VA-Standard-Membrane-Cartridge is removed. This prevents water from running out of the VA-Standard-Membrane-Head in an uncontrolled manner and causing damage to the water treatment system or the environment.

The VA-Standard-Cartridge-System is modern, robust and safe. It is also perfect as an assembly kit to realise your water filter variations.

Login

No reviews found. Share your insights with others.

Subscribe to our newsletter

Subscribe to our newsletter and always stay up to date!

You can unsubscribe from the newsletter at any time. You will find the unsubscribe link at the end of every newsletter message. Of course, your data is transmitted via a secure connection, treated confidentially, and not shared. Information about data processing can be found in our data protection declaration.